SFX BMT40 BMT45 BMT55 BMT65 Driven Tool Holders BMT Axial and Radial Live Tool Holders

SFX BMT40 BMT45 BMT55 BMT65 Driven Tool Holders BMT Axial and Radial Live Tool Holders

Free Shipping

Couldn't load pickup availability

High-Quality BMT40 BMT45 BMT55 BMT65 Driven Tool Holders for Enhanced Machining Precision and Stability BMT Axial and Radial Live Tool Holders

Model Explanation: J: Angular Contact Bearing;Y: Tapered Roller Bearing;W: External Clamping; N: Internal Clamping

Critical Parts Made from Imported Materials: Japanese NSK Bearings Swedish Oil Seals German Grease

Gear Ratio: i = 1:1 Maximum Speed: 6000 rpm Body Accuracy: 0.003mm

High load capacity and rigidity: The 90° radial driven tool holder features preloaded double tapered roller bearings, significantly improving rigidity compared to traditional ball bearings, ensuring more stable machining performance.

Quality assurance and durability: Crafted with premium resources for superior quality, each driven tool holder is built to last, offering long-term durability.

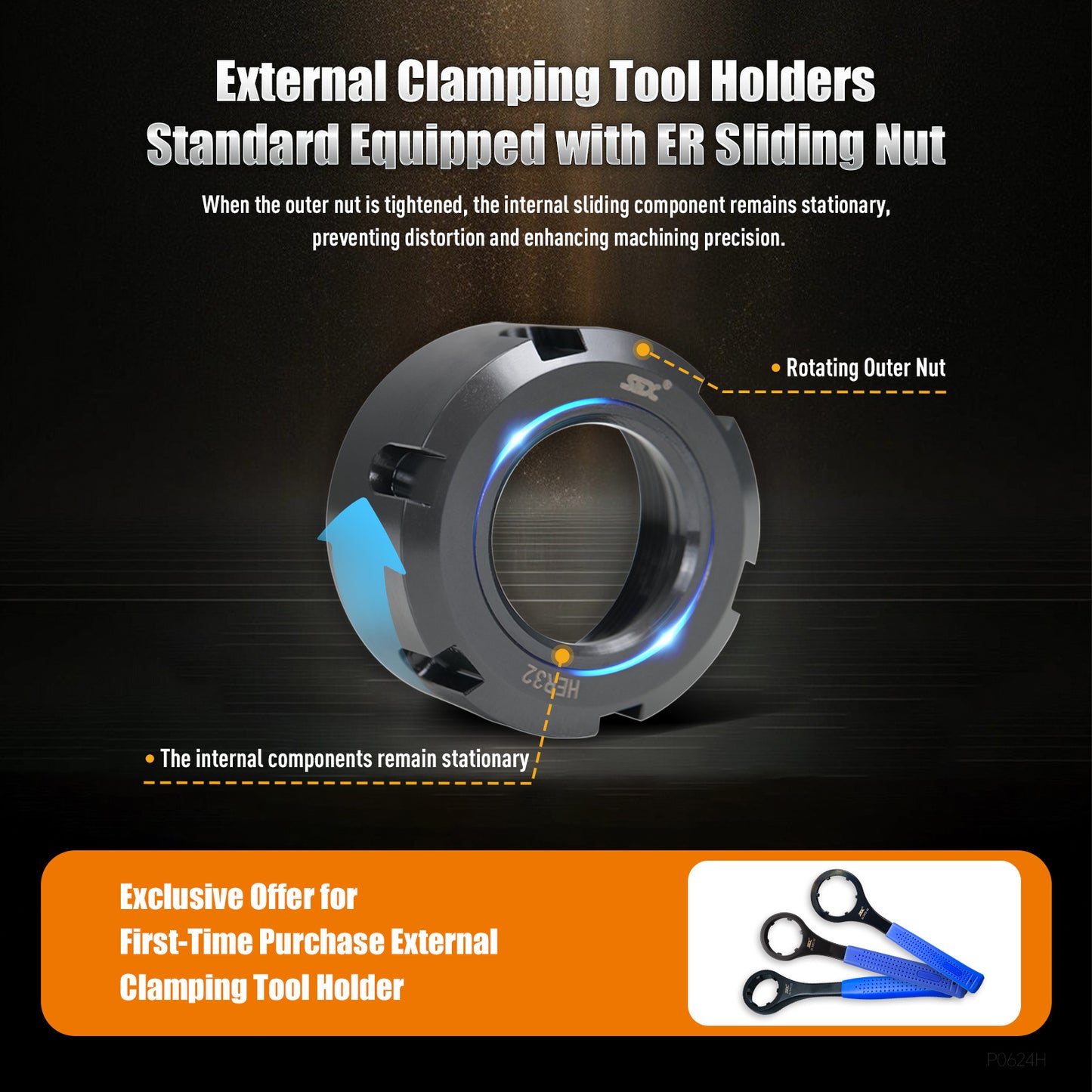

Standard equipped with ER friction bearing nut: When the outer nut is tightened, the internal sliding component remains stationary, preventing distortion and enhancing machining precision.

Exclusive Offer for First-Time Purchase External Clamping Tool Holder.

Stringent precision testing and running-in inspection: Each tool holder undergoes precise testing and running-in inspection before shipment, ensuring optimal control over thermal rise and noise, improving product stability and durability.

Warranty and After-Sales Service

1-Year Warranty: Includes two annual maintenance services during the warranty period, with customers covering one-way shipping costs.

1 to 2 Years Post-Purchase: Maintenance services will incur a $20 labor fee per unit per visit (parts cost not included), with customers covering round-trip shipping costs and any customs duties (if applicable)

How to Choose the Right Model:

If you're unsure whether this is the right model for your application, you can verify the following parameters:

Hole Distance: Compare the distance between the mounting holes to ensure compatibility with your tool turret.

Mounting Dimensions: Verify the dimensions of the part that installs into the turret to ensure a secure and proper fit.

Please refer to the technical datasheet for detailed specifications and compare them with your machine's requirements.